In partnership with: ABP Food Group

Helping The UK's largest beef processor serve more, for less

In partnership with: ABP Food Group

Helping The UK's largest beef processor serve more, for less

ABP is the largest beef processor in Ireland and the UK, working with more than 35,000 farmers and employing over 11,000 people in 46 manufacturing plants around Europe.

As the first food company to be awarded a triple certification from the Carbon Trust and a founding member of Origin Green - Ireland's food and drink sustainability programme - ABP Food Group is focused on environmental best practice. So, when ABP needed a partner to develop renewable generation capabilities and improve energy efficiency, they called on ESB Energy Business Solutions

"Sustainability is embedded within our culture. Our partnership with ESB Energy provides the expertise and financing support to achieve our most ambitious goals for carbon reduction."

John Durkin

Sustainability and Environmental Manager, ABP

The Challenge

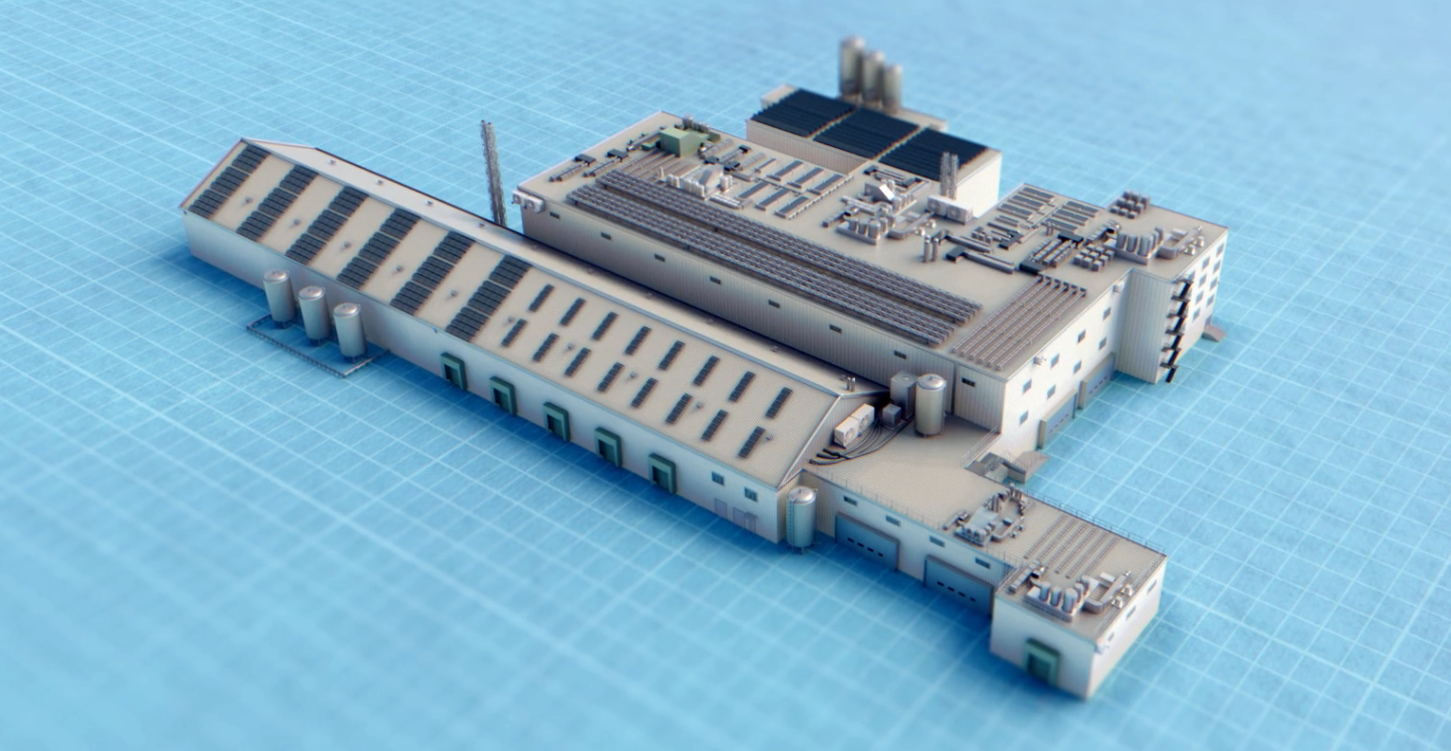

Like all food and drink manufacturers, meat processing relies on the availability of constant refrigeration and a reliable supply of hot water - both of which requires significant energy. ABP wanted a way to reduce energy usage and cut carbon emissions at two of its Irish plants, to support its journey to carbon zero.

The Solution

Following a detailed analysis of the energy usage at each plant, ESB Energy worked in partnership with ABP to design the solutions. In addition to ESB's global energy expertise, ABP was also able to avail of ESB's £75m decarbonisation fund.

This funding enables ABP to adopt the latest technology with no up-front investment. Costs are offset by energy savings, helping ABP realise its sustainability strategy of doing more with less.

The Technology

At ABP's Cahir plant, a waste heat recovery and thermal storage system was developed, allowing the plant to recover heat generated by the refrigeration system and significantly reduce energy costs.

With a boiler run on fossil fuels and a refrigeration system generating substantial waste heat, ABP's Clones plant is set to receive a total energy make-over. Ground source heat pumps will provide the majority of hot water, while heat capture and thermal storage technologies will recycle waste heat from the refrigeration process.

An energy and carbon monitoring system will facilitate ongoing equipment optimisation and cost savings. Once complete, the entire system will save over 1,700 tonnes of carbon emissions annually - a reduction of over 80% compared to the old system.

The Results

- 66% reduction in energy usage projected

- 80% reduction in carbon emissions per year projected, equivalent to 1,700 tonnes

- Electrification of heat significantly reduces fossil fuel reliance

- Ongoing energy cost savings

The Competitive Advantages

- Sustainable practices benefit stakeholders

- Sustainability credentials appeal to shareholders and consumers

- Funded solutions frees capital for further innovation

Dramatically Reduce Your Energy Cost

ESB Energy works in partnership with large energy users to deliver sustainable solutions that dramatically reduce energy costs and carbon emissions.

- Unparalleled expertise in the energy sector

- An international network of technology partners

- Advanced energy monitoring and analytics

- Project financing with no upfront investment required

Arrange a call back→